|

ISMS™ is a Distributor for MP

Systems High Pressure Coolant Pump Systems.

MP

Systems Coolant Pumps are for

turning, milling, & grinding applications. Use with Swiss-style lathes, conventional

lathes, machining centers & grinders. MP Coolant Pumps handle oil or water

based coolants. |

|

|

Tooling,

Workholding, Tool Holders & Accessories for Automatic Screw Machines

& CNC Turning & Milling; Davenport® Parts, Attachments, Machines

& Services |

|

CHOOSE MP SYSTEMS

HIGH-PRESSURE COOLANT PUMPS FOR TURNING, MILLING, & GRINDING

APPLICATIONS |

|

ISMS distributes MP Systems high pressure coolant pump systems,

developed

specifically for use with Swiss style lathes, conventional lathes,

machining centers & grinders. MP Pumps are designed

to handle oil or water based coolants. MP Coolant Pumps are

operator friendly,

essentially leak-free, reliable & easy to maintain.

|

|

High Pressure Coolant Systems by MP Systems:

- Are ruggedly built of the highest

quality components

- Rigorously designed and tested in

the real machine tool world

- Provide you with reliable,

dependable performance

- Easier to remove / replace filters

than most models in the marketplace

- All of the machine components,

including filters are housed conveniently and neatly inside the

cabinet assembly

- Superior Filtration - 5µ removes

suspended chips and grit to keep coolant clean in the cutting

zone, increasing tool life

"Which High Pressure Cooling System Do I Need?" -

MP Systems offers

High & Medium Pressure Cooling Systems. |

|

|

|

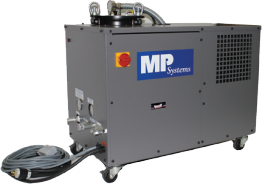

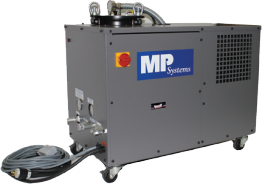

MP Systems V2 Series

High Pressure Coolant Pumps

Versatile, Compact System for a Variety of Machines

The V2 is a general

purpose, compact-design high pressure coolant system. The most

recent addition to MP Systems’ new generation product line, the V2

houses all of its internal components within a high quality

sheet-metal frame body designed to fit under a standard height bar

feeder. Premium castors allow easy relocation of the pump on the

shop floor. A heat exchanger is an added option.

Like all MP Systems High

Pressure Coolant systems, the V2 series is low maintenance and

longer lasting due to its patented diaphragm pump. |

|

|

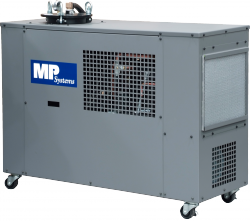

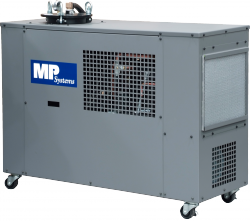

MP Systems R Series High Pressure Coolant

System

The Most Versatile High Pressure Coolant Systems for the Machine Tool Industry

MP Systems' R Series high pressure

coolant systems are designed for the general machine tool market.

These dependable, rugged systems are excellent coolant systems for

the following machine tools:

- Machining Centers

- 3 & 4 Axis Lathes

- Multi-Function Machine Tools

- Grinding Machines

R Series high pressure coolant

systems feature built-in reservoirs. MP Systems high pressure

coolant systems use diaphragm pumps for higher performance, longer

pump life, less repair down time, and fewer service calls than

conventional piston style pumps. |

|

|

MP Systems S2 Series - Combination HP Coolant System/Chiller

Minimize floor space. Maximize productivity.

An all-in-one integrated chiller and

high pressure coolant system, the S2 was designed specifically for

the metalcutting industry, accommodating the growing need for high

pressure, stabilized coolant to help maintain the tight tolerances

of many parts.

Our engineers have dedicated a

substantial amount of time to developing the S2 which we believe

solves all of the problems associated with other coolant-chiller

products currently available including:

- Space Saving Design

- Optimal Flow

- Real-Time Monitoring

- Tidy Hose Routing

|

|

|

MP Systems EFO Series

High Pressure Pump - Economy "E" Series

Economy System for Smaller Machines and Budgets

MP Systems' E Series (Economy) high

pressure coolant system is a basic diaphragm driven machine tool

system that delivers up to 3 GPM flow through a single high pressure

coolant port. The EFO can be used with oil or water and allows up to

1,000 PSI.

Like all MP Systems High Pressure

Coolant systems, the EFO series is low maintenance and longer

lasting due to its patented diaphragm pump.

Recommended for 30 taper machines

with tooling 1/2" in diameter and smaller. |

|

|

|

MP Systems VR Series

High Pressure Coolant Pump

The VR Series is designed for maximum

performance for a variety of tooling sizes & multi-function

machines.

MP Systems' VR Series high pressure

coolant systems are variable flow with programmable pressures. These

dependable, robust systems are excellent coolant

systems for the following machine tools:

- Machining Centers

- Multi-Axis Lathes

- Multi-Function Machine Tools

|

|

BENEFITS OF USING

HIGH-PRESSURE COOLANT PUMPS FOR TURNING, MILLING & GRINDING

APPLICATIONS: |

|

|

|